Blog

The Ultimate Guide to Woodworking Safety Practices: Protect Yourself in the Workshop

Woodworking safety practices are essential for anyone who wants to enjoy this creative craft without risking their fingers, eyes, or worse. I’ve spent years in workshops and seen too many close calls that could have been avoided with proper precautions. This guide covers everything you need to know to stay safe while creating beautiful woodworking projects. Whether you’re a weekend hobbyist or a serious DIYer, these safety practices will keep you woodworking for years to come.

Why Woodworking Safety Should Be Your #1 Priority

Let’s get real: woodworking is inherently dangerous. You’re using sharp tools, powerful machines, and creating dust and debris that can harm your body in both the short and long term. I’ve had my share of close calls, and each one reinforced that no project is worth losing a finger over.

The most common woodworking injuries include lacerations, amputations, eye injuries, hearing damage, and respiratory issues. Many of these happen in a split second of inattention or when trying to take a “just this once” shortcut. Trust me, the extra few minutes it takes to set up properly is worth it when compared to a trip to the emergency room.

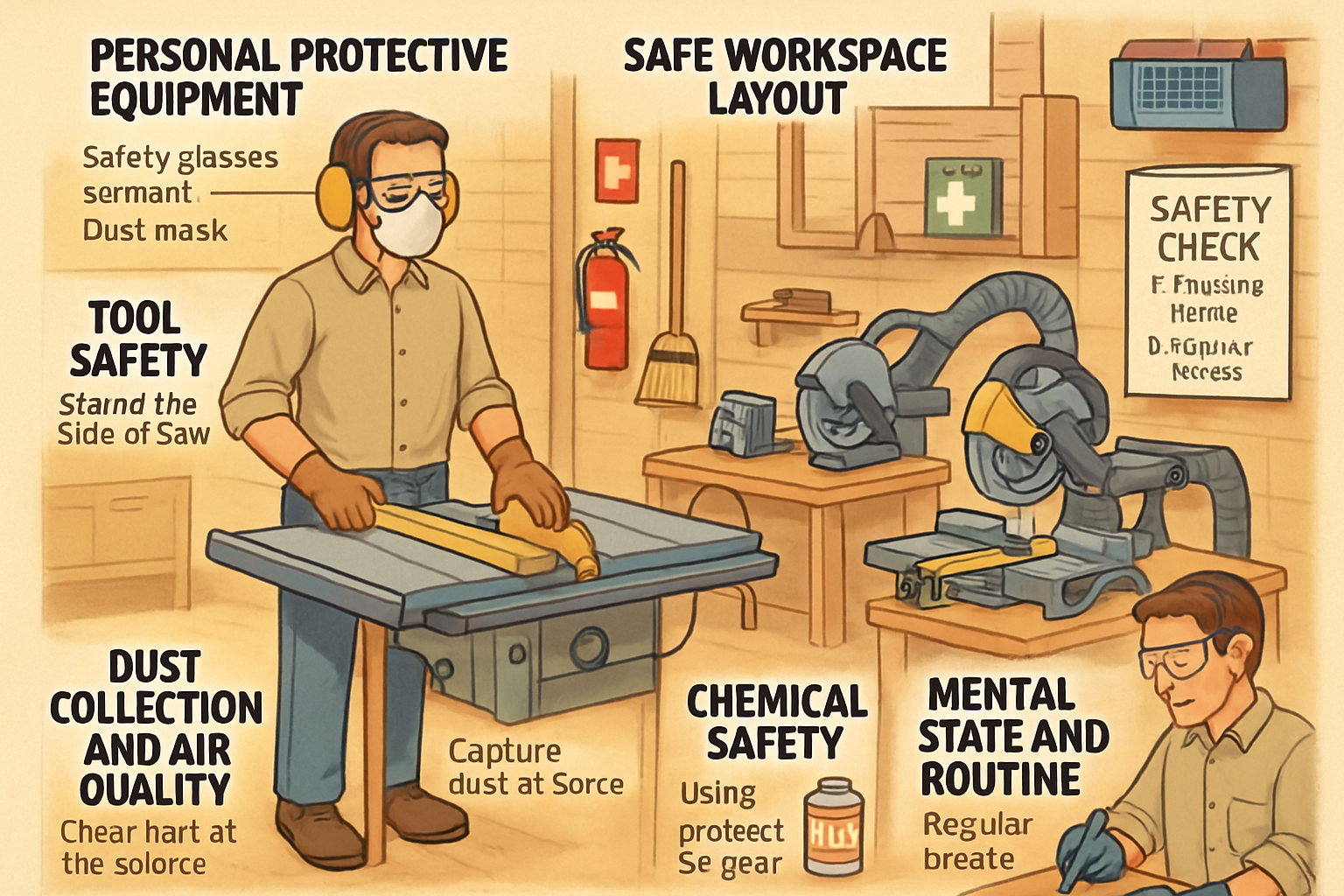

Essential Personal Protective Equipment for Woodworkers

Your body is irreplaceable, and protecting it should be your top priority in the workshop. Here’s the PPE you should never compromise on:

Eye Protection: Your Vision is Irreplaceable

Wood chips fly at incredible speeds when cutting. Always wear safety glasses that meet ANSI standards – not regular glasses, not sunglasses, but actual impact-resistant safety glasses. I keep multiple pairs around my shop so I’m never without protection, even when visitors stop by.

Hearing Protection: Preserve Your Hearing

Power tools operate at noise levels that can permanently damage your hearing. A quality pair of earmuffs or earplugs is essential when using machines like table saws, routers, or planers. Remember, hearing damage is cumulative and irreversible. I’ve known too many old-timer woodworkers who can barely hear a conversation because they skipped this simple protection.

Respiratory Protection: Your Lungs Matter

Wood dust isn’t just annoying – it’s classified as a carcinogen. Different masks serve different purposes:

- Dust masks: For basic protection during light sanding

- N95 respirators: For more serious dust exposure

- Half-face respirators: For finishing work with solvents and chemicals

I always wear at least a dust mask, even for “quick cuts” – because there’s no such thing as a safe amount of wood dust in your lungs.

Creating a Safe Woodworking Environment

Safety starts before you even pick up a tool. Your workspace setup dramatically impacts your risk level.

Workshop Layout for Maximum Safety

A well-organized shop prevents accidents. Ensure you have:

- Adequate space around each machine (especially for material infeed/outfeed)

- Non-slip flooring free of sawdust and debris

- Proper lighting so you can clearly see your work

- Fire extinguisher within easy reach

- First aid kit stocked and accessible

I reorganized my shop after a near-miss when a board kicked back because I didn’t have enough clearance. The extra hour spent rearranging saved me from potential injury.

Electrical Safety in the Woodshop

Woodshops have unique electrical concerns:

- Use GFCI outlets to prevent shock, especially important in potentially damp environments

- Don’t overload circuits with multiple high-draw tools

- Keep cords away from cutting paths and foot traffic

- Inspect tool cords regularly for damage

I once had a close call when a damaged cord sparked near wood shavings. Now I inspect every cord before plugging in.

Safe Operation of Woodworking Power Tools

Power tools make woodworking more efficient but also introduce serious hazards. Here’s how to use the most common ones safely:

Table Saw Safety: Respect the Beast

The table saw causes more serious injuries than any other woodworking tool. Always:

- Use the blade guard and riving knife whenever possible

- Stand to the side of the blade (not directly behind it) to avoid kickback injuries

- Use push sticks for narrow cuts to keep hands away from the blade

- Never free-hand cut on a table saw – always use a fence or miter gauge

I know too many woodworkers missing fingers because they thought they could make “just one quick cut” without proper setup.

Router Safety: Controlling the Tornado

Routers spin at incredibly high RPMs and demand respect:

- Ensure bits are tight and in good condition

- Always move the router against the rotation of the bit

- Secure your workpiece with clamps, not hands

- Let the tool come to full speed before contacting wood

I always do a “dry run” with the router unplugged to make sure my hands will stay in safe positions throughout the cut.

Miter Saw and Circular Saw Safety

These common tools require specific precautions:

- Wait for the blade to stop completely before lifting the saw

- Keep both hands on the tool in designated grip areas

- Secure material properly before cutting

- Check that blade guards return properly and aren’t stuck

When using these tools, I mentally trace the cutting path and make sure nothing (including body parts) is in the danger zone.

Hand Tool Safety: Still Dangerous if Misused

Don’t underestimate hand tools – they can cause serious injuries too.

Sharp Tools: Chisels, Planes, and Hand Saws

Counter-intuitively, sharp tools are safer than dull ones because they require less force to use:

- Keep edges sharp and properly maintained

- Always cut away from your body

- Store tools with edges protected

- Use bench hooks and vises to secure work instead of holding it in your hand

I learned this lesson the hard way when a dull chisel slipped and went into my palm instead of the workpiece.

Hammers, Mallets, and Impact Tools

These simple tools still cause plenty of injuries:

- Ensure handles are secure and not cracked

- Wear eye protection (flying nail heads are common)

- Use the appropriate size and type for the job

I keep different hammers for different tasks and never use a metal hammer on hardened steel chisels – that’s asking for metal fragments in your eye.

Proper Woodworking Attire and Body Positioning

What you wear and how you stand make a huge difference in workshop safety.

Dress for Woodworking Success

Proper attire includes:

- No loose clothing that could get caught in machinery

- No dangling jewelry or accessories

- Closed-toe, non-slip shoes

- Long hair tied back

- Consider task-specific items like cut-resistant gloves for certain operations

I once had a loose shirt sleeve catch in a drill press – luckily I hit the stop button quickly, but it taught me to always roll up sleeves or wear fitted clothing.

Body Positioning and Ergonomics

How you position yourself matters for both safety and long-term health:

- Stand with a solid, balanced stance when operating tools

- Position your body so if slips occur, you fall away from cutting edges

- Work at proper height to avoid back strain

- Take breaks to prevent fatigue (tired woodworkers make mistakes)

I built my workbenches at the perfect height for my body, which reduces fatigue and helps me maintain control of tools and materials.

Dust Collection and Air Quality

Wood dust is both a safety hazard (fire, explosion) and health hazard (respiratory issues, cancer).

Dust Collection Systems: More Than Just Cleanliness

A proper dust collection system should:

- Capture dust at the source whenever possible

- Use appropriate filtration (HEPA filters for fine dust)

- Be properly grounded to prevent static buildup

- Be regularly emptied and maintained

I invested in a cyclone dust collector and it’s been game-changing for both shop cleanliness and my health.

Air Filtration for Invisible Particles

Even with good dust collection, airborne particles remain:

- Use overhead air filtration systems

- Open windows or doors when weather permits

- Wait for dust to settle before removing your mask

I run my air filter for 30 minutes after finishing work to clean the air before my next session.

Chemical Safety in Woodworking

Finishes, adhesives, and solvents introduce additional hazards.

Safe Handling of Finishes and Solvents

Many woodworking chemicals are flammable, toxic, or both:

- Read and follow all manufacturer safety instructions

- Use in well-ventilated areas

- Wear appropriate protective gear (gloves, respirators)

- Dispose of rags properly to prevent spontaneous combustion

I soak all oil-finish rags in water and store them in a metal can with a lid until disposal – it seems excessive until you hear stories of shops burning down from improperly stored rags.

Understanding Chemical Risks

Different products have different hazards:

- Water-based products are generally safer but still require ventilation

- Oil-based products often contain more harmful VOCs

- Two-part finishes may have special handling requirements

I’ve gradually switched to water-based finishes for most projects, reserving solvent-based products only for when absolutely necessary.

Emergency Preparedness in the Woodshop

Despite best precautions, accidents can happen. Be prepared.

First Aid Essentials

Your workshop first aid kit should include:

- Bandages of various sizes

- Sterile gauze pads

- Medical tape

- Antiseptic wipes

- Eye wash solution

- Emergency contact information

I also keep a tourniquet in my shop – it’s extreme, but in case of a severe cutting injury, it could save a life.

Fire Safety and Prevention

Woodshops have abundant fuel for fires:

- Keep at least one ABC-rated fire extinguisher visible and accessible

- Know how to use your extinguisher before you need it

- Have an evacuation plan

- Consider a smoke detector specifically for your shop space

I conduct a “fire hazard check” at the end of each shop session, making sure machines are off, dust is cleaned up, and chemical rags are properly stored.

Mental Approach to Woodworking Safety

Safety is ultimately about mindset and habits.

The Right Mental State for Woodworking

Never work when:

- Tired or fatigued

- Under the influence of alcohol or medications that affect alertness

- Rushed or distracted

- Emotional or angry

I’ve learned to walk away when I’m not in the right headspace. The work will still be there tomorrow, but mistakes made while distracted could be permanent.

Building Safety Habits and Routines

Develop consistent safety practices:

- Do a pre-work safety check of tools and environment

- Mentally rehearse operations before starting

- Clean as you go to prevent hazards

- Develop a shutdown routine that includes safety checks

I have a laminated checklist near my shop door that I review before starting any session, ensuring I don’t miss critical safety steps.

Continuous Learning for Woodworking Safety

Safety knowledge is always evolving, and there’s always more to learn.

Staying Current with Best Practices

The woodworking community constantly develops better safety approaches:

- Follow woodworking publications and websites

- Join woodworking groups or forums

- Consider taking classes or workshops that emphasize safety

- Review tool manuals regularly

I make a point to watch safety-focused videos monthly to refresh my knowledge and learn new techniques.

Teaching Others Safe Woodworking

If you share your shop or mentor others:

- Always prioritize safety instruction before project instruction

- Set a good example by always following safety practices yourself

- Don’t allow shortcuts or unsafe practices in your shop

When I teach friends woodworking, the first session is always focused on safety fundamentals, not projects.

Conclusion: A Lifetime of Safe Woodworking

Woodworking is a rewarding pursuit that can last a lifetime if you prioritize safety. The extra time spent on safety practices is a small investment compared to the potential cost of an injury. Remember that no project is so important or urgent that you can’t take the time to do it safely. By implementing the woodworking safety practices in this guide, you’ll be able to enjoy this wonderful craft for years to come, with all your fingers intact and your health preserved. Stay safe in the shop, and the beautiful projects will follow.